QSC’s SC-444 Screen Channel Loudspeaker System

Ever since it was first introduced over 14 years ago, no other screen channel loudspeaker has come close to matching the performance and utility of QSC’s SC-444 Screen Channel Loudspeaker system. It was, and is still, simply the best large room cinema system available. From top to bottom, here are sixteen reasons why.

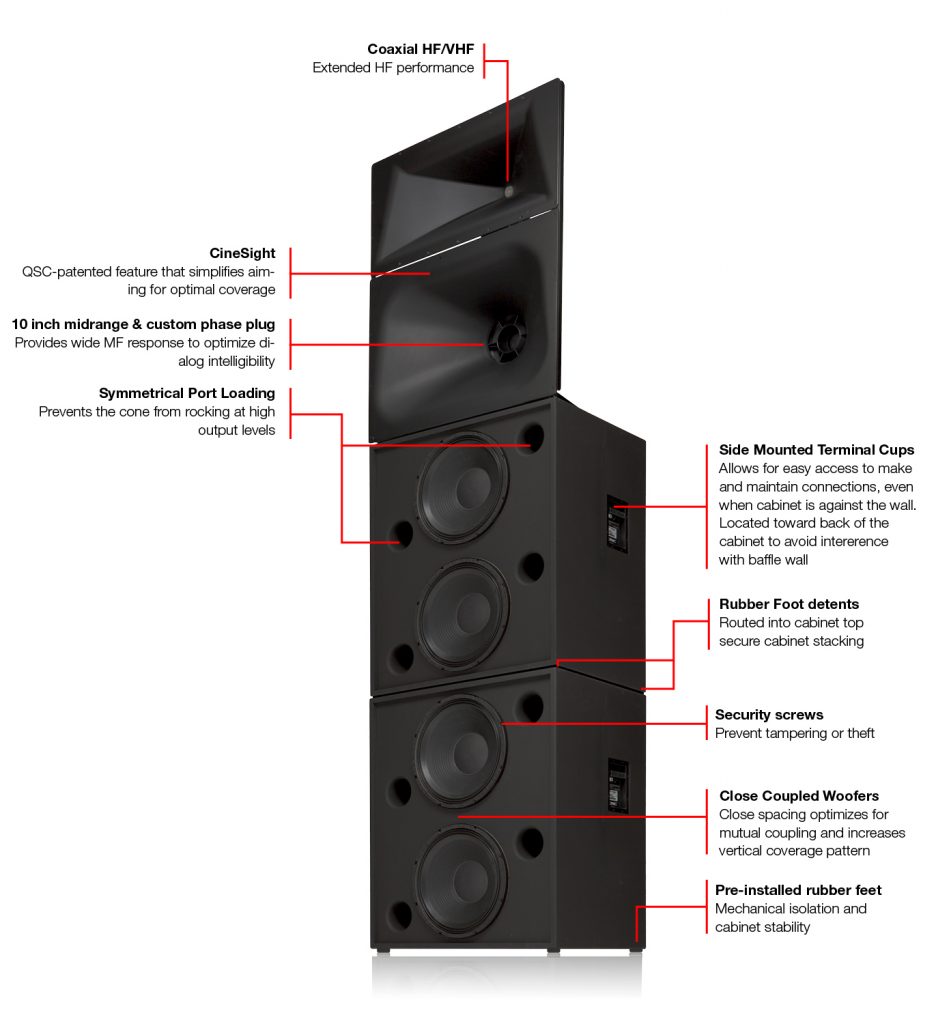

1. Coaxial HF/VHF

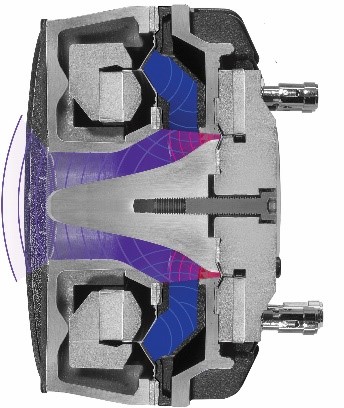

From about 1.7 kHz on up, the SC-444 uses a unique high-frequency (HF)/very high frequency (VHF) coaxial compression driver, which features two diaphragms with less mass than traditional diaphragms, each optimized for its share of the frequency spectrum, resulting in exceptional dynamic range, extended high frequency response and lower distortion.

2. 10 inch Cone Midrange

A key attribute of any high performance screen channel system is its ability to reproduce the human voice with the utmost clarity, intelligibility, and fidelity. Dialog is the domain of the midrange loudspeaker, and it is well-recognized that cone drivers produce the smoothest, most natural sounding dialog of any loudspeaker type. The SC-444 features a high power handling 10 inch cone driver and custom phase plug which provides wide midrange response at any power level.

3. CineSight™

QSC was the first loudspeaker manufacturer to integrate aiming capability into the structure of the MF/HF horn, with its patented CineSight aiming device (US patent 7,367,423). This simple-to-use device coupled with the distinctive physical design of the horn section makes it easy to aim for optimal coverage in any size room.

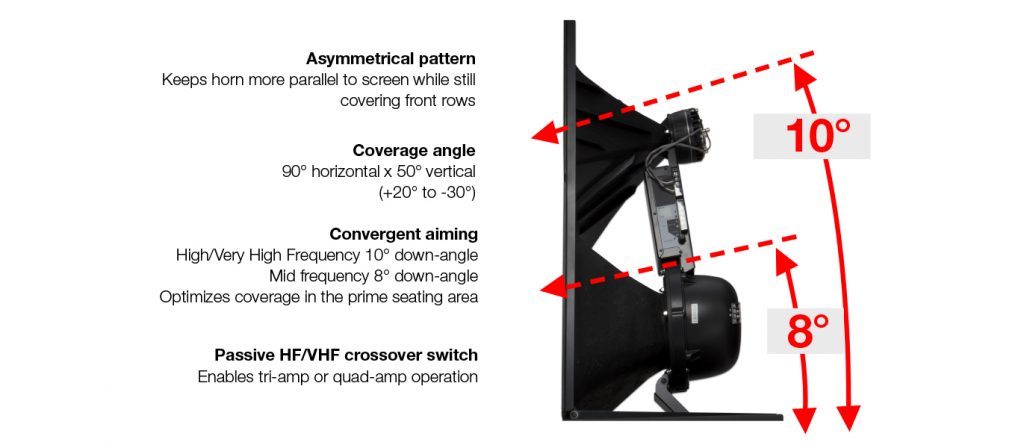

4. Built-in Convergent Aiming

Although the MF and HF horns act as a single unit, each horn is formed with a different built-in aiming angle designed to converge on the other side of the screen in the seating area, providing coherent midrange to very high frequency coverage from front to back. The top mounted horn is tilted down at a greater angle to converge with the lower horn. See Barry Ferrell’s blog “Aim to Please” for more information.

5. Pan and Tilt Aiming

The SC-444’s unique pan-tilt mechanism for the mid-high section makes quick work of assembling and aligning screen channel systems. The assembly is labeled for repeatability and features a notched tilt adjustment to maintain vertical alignment even if the bolt comes loose. The pan adjustment is “dual pivot” to prevent the horn edge from going behind the baffle wall as it pivots from side to side.

6. Asymmetrical Pattern

Both the midrange and high frequency horns are designed with an asymmetical vertical coverage pattern so that when the MF/HF horn section is installed exactly parallel to the screen, the coverage ranges from 20 degrees above centerline to 30 degrees below centerline. Keeping the MF/HF unit parallel to the screen minimizes intelligibility-damaging reflections from the rear of the screen surface.

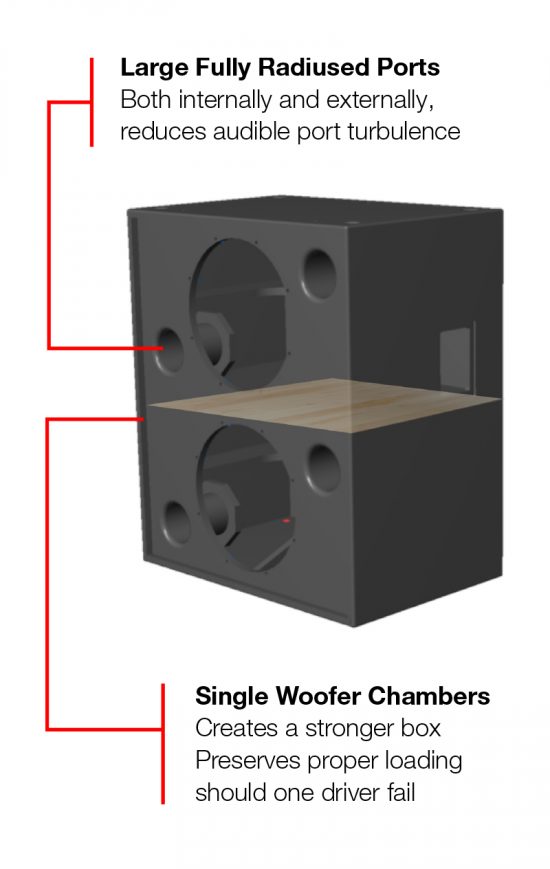

7. Single Woofer Chambers

The low frequency enclosure has a built-in panel that separates each woofer in its own chamber. This panel not only enhances structural integrity of the enclosure, but also maintains optimal “loading” of each driver. In the unlikely chance that one driver fails, it will not affect the sound quality delivered by the other one.

8. Fully-Radiused Ports

Low frequency drivers (woofers) displace a large volume of air, which vents from the inside of the enclosure at high velocity through the ports. When the port tubes have sharp, 90-degree edges, the sound will refract over the edge and can produce an audible noise called port turbulence. All QSC low frequency enclosures use port tube structures that are fully radiused (or rounded) both on the outside and inside of the enclosure, which minimizes audible port turbulence.

9. Symmetrical Port Loading

Both ports are designed to balance the pressure load inside the enclosure on the rear of the woofer cone, ensuring linear movement of the woofer, which minimizes “rocking” and distortion at high sound pressure levels.

10. Pre-installed Rubber Isolators

For almost 30 years, installers have adopted the best practice of using isolation pads to minimize very low frequency energy transmission to the mounting platform, which can create audible noise and cabinet movement. All QSC low frequency enclosures feature pre-installed neoprene “feet” to eliminate both of these potential problems.

11. Isolator Indents

Routed into the top of each cabinet is a round detent, perfectly sized to match the pre-installed rubber feet of the top LF enclosure, so that when two are stacked one on top of the other, there is little chance of any movement.

12. Close-Coupled Woofers

It’s a well-known acoustical phenomenon that when two drivers are mounted as closely together as possible, they will perform almost as one, with an additional 3 dB of output. This is known as “mutual coupling”. That’s why we design our enclosures so that the woofer mounting brings them as physically close together as possible, both within a single enclosure and between multiple enclosures.

13. Security Hardware

Woofer theft is a well-known risk when loudspeakers are installed where people can access them. The woofers in the LF enclosures of the SC-444 are installed with special security screws that require a non-standard screwdriver head for removal.

14. Shallow Depth

All QSC LF enclosures are no more than 20.25 inches (514.4 mm) in depth. This industry-leading design facilitates installation especially where space is limited behind the screen.

15. Side Mounted Terminal Cups

The terminal cup is where wiring connections are made to the LF enclosures. All QSC LF enclosures feature terminal cups that are located on the side panel so they’re accessible even if the enclosure is pushed against the wall. Also, the cup is positioned off-midline toward the rear of the cabinet, avoiding the possibility of interfering with or being blocked by the baffle wall.

16. Tri-amp or Quad-amp Operation

Since no single loudspeaker component can effectively reproduce the entire audio spectrum, loudspeaker system designers rely on frequency dividing networks (or crossovers) to divide the overall frequency range among multiple specialized drivers designed for optimal performance for a given frequency range. Crossovers can be “active” (discrete electronic networks or software-based DSP), or “passive”, requiring no additional electronics or signal processing. While properly designed passive networks deliver very good results, it’s generally recognized that the best possible performance is only achieved with active signal processing, using a separate power amplifier channel for each loudspeaker component and frequency range. The SC-444 can be operated either in tri-amp mode (which uses three amplifier channels for LF, MF, and HF/VHF with a passive network between the HF and VHF diaphragms of the coaxial driver), or quad-amp mode (where a single amplifier channel is used to power each of the four driver sections individually). The passive HF/VHF crossover is possible because of the inherent time alignment of the coax driver. Separate drivers at different depths would require active crossovers with digital delay to compensate for the different mounting depth.

While the SC-444 is recommended for the largest cinemas, it’s important to note that the smaller SC-424 offers all of the same features and performance, but uses a single 2×15 low frequency enclosure for medium to large rooms.

Click here (or click the download button below) for an infographic that describes all of the industry-leading features of the SC-444 Screen Channel Loudspeaker System and please be sure to reach out to us directly or in the comments section if we can provide more details on the SC-444 or any other QSC product.

Great post for a great speaker